The Fundamentals of Flow Production for Photo Studios - with Lean Principles

Every year we all hear the same thing. We need things done faster, we need more done, and we need it all without any mistakes. If you're ready to speed things up and save some time, it might be time to look at your studio's production workflows—retooling them in truly optimized ways from the ground up in many cases.

Three of the principles of lean—reducing lead times, decreasing work-in-progress, and increasing throughput—can easily be applied to high volume photo studio environments to achieve what we call, flow production. In the final episode of our Remote Studio Solutions webinar series, we explored this philosophy and how it can enable studios to succeed immediately and produce more in the long run across the production process. Simplifying the processes into an assembly line of sorts.

Below the Table of Contents (because there's a lot of info) you'll find a summary of the conversation about flow production on the Remote Studio Solutions webinar series with my colleagues James and Jasper.

What is Flow Production?

Before we get into the nitty-gritty, let's start with the basics of flow production.

Flow production in photo studios transforms a chaotic jumble of tasks into a harmonious symphony of creativity. It's all about crafting a seamless workflow that enables photographers to bring their visions to life - and still do it as mass production.

At the heart of flow production lies the idea of continuous movement, with each step in the process flowing smoothly into the next. No longer relying on a batch production process or waiting for folder after folder of content to be delivered all at once. Instead, each action is carefully choreographed, like efficient dancers in a ballet, to produce a final product that sparkles with brilliance.

So if you're a photographer looking to elevate and scale your craft, embrace the flow production process and experience the magic of a seamless, effortless workflow. The assembly line is open for business.

It's time to focus on the continuous production, not the constant chaos.

Examples of Flow Production

The following are a few examples of where flow production with continuous movement could be implemented because the steps are often repeated for most shoots. The flow production process helps to ensure that each step is completed efficiently and effectively. By streamlining the production process, photo studios can produce high-quality images more quickly and at a lower cost, which can help scale, and increase profitability, speed, reputation, and so much more.

Preparation and Setup:

This job involves preparing the studio space, setting up lights and backdrops, and preparing the camera equipment and assembly line.

Capturing the Images:

Photographers use their cameras to capture the images, and the teams make any necessary adjustments to lighting, composition, and other settings.

Reviewing and Selecting Images:

This job involves photographers reviewing the images they have captured and selecting the best ones for further processing.

Retouching and Editing:

Selected images are processed and edited using image editing software to enhance their quality, color balance, and other aspects.

Delivering the Final Product:

The final images are saved in the appropriate format and then delivered to the client.

Post-Production:

This job involves archiving the images, backing up files, and updating clients on the next steps.

It Wasn’t Love at First Sight

While he’s now an advocate for applying lean principles to studio production, James hasn’t always felt that way. His introduction to the philosophy came by way of an unpleasant imposition while he was heading up studio operations at John Lewis, a large UK-based retailer, back in 2012.

It was a rocky beginning, to say the least. Several lean consultants were brought in by his executive leadership to speed up their online launch and James was anxious about how it would go and, truth be told, more than a little upset about it.

The team had just gone through a major restructuring and process optimization exercise which, by all objective measures, had been a great success. They had improved productivity by 155% and were feeling pleased with their achievements and confident about what they were doing.

He knew this announcement would come as a blow and it was tough to break the news to his team. Especially given the widely held negative perceptions of lean—which is often wielded as a way to justify reduced head counts in the name of eliminating redundancies.

James also didn’t know how they’d respond to the starting of another major initiative so close on the heels of what they’d just undergone.

He was keenly aware that change fatigue might soon set in if this system didn’t go well or produce incredible results.

Pardon Me, You Want to Do What?

James wondered how these lean consultants, who had never stepped foot in his studio, met his team, nor seen their ways of working, drive meaningful changes to improve processes.

Let alone the ambitious charter they had to tackle ALL of these:

- Improving image quality standards

- Reducing the lead time it took to produce photography

- Increasing sales and margin

- Making samples available to wider business earlier

- Reducing the cost per shot

- Increasing the number of shots

"To say that I was a little bit miffed when lean was being imposed on me is putting it mildly. In truth, I was pretty pissed off. And actually, fairly scared about the impact this was going to have on my team. There was some anxiety about what this might mean. All in all, we were pretty fearful. I was conflicted because I was frustrated but also nervous about how my team would feel about it." - James

Validation: Disproving the Rule

While the consultants were very disciplined in their approach to applying lean principles they were also very academic and didn’t understand the commerciality of certain aspects of photography in the studio, like batch production.

Their view was that batch production was bad in all cases. And while James believed (and now strongly advocates) that batch production can be a real evil leading to an inefficient production process, sometimes it is necessary for economies of scale.

For example, on-model photography is a very expensive undertaking and unless you’re going to shoot 40-50 items in a day you’re not getting a good return on the investment. It necessitates batching those items and their production—it’s the only way to do it and the consultants hadn’t understood that.

James had found and latched on to the example he needed—the proof that allowed him to disprove their theory which only led to more butting heads.

From Skeptic to Evangelist: The ‘Aha’ Moment

But then things changed.

When starting out they analyzed risks and mitigations to see where this undertaking might break down. One of the main risks James identified was the change fatigue his team might experience and how they would get them on board to endorse and buy into this process.

After some time the consultants responded to James’ primary concern with understanding and appreciation. The real lightbulb moment came when he realized they were interested in truly working as his partners—helping his team achieve even greater success.

They were in agreement that the best way to ensure the initiative succeeded was to include his team in the process every step of the way.

Their first order of business was to set out with a Kaizen event, a rapid improvement exercise, designed to get the team involved.

"I love the fact that the team and people who are actually working in the process are so key to delivering problem solutions and improvements in lean." - James

Principles in Action

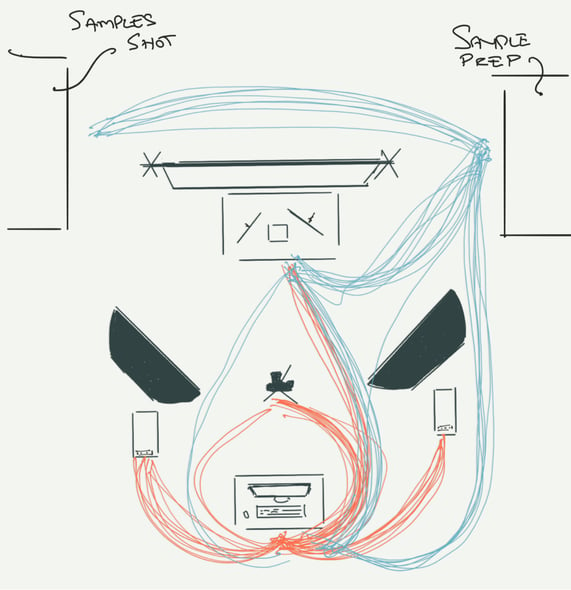

To get started they pulled a standard day’s worth of product to shoot, set up some GoPro cameras, and just set about shooting. The team then went about their normal work for several hours, with the GoPros running.

After they had finished their shooting for the morning they went into a meeting room to watch the video playback together.

The team was asked to keep an eye on the photographer as he set about his work moving through the studio space to fiddle with lighting packs, adjust exposure, change the staging for particular products, and finally capture each shot.

They then went through the same exercise while watching the assistant attend to her tasks—prepping samples, checking the monitor, moving products that had been shot, and changing the set over from tabletop to overhead and back again.

The outcome of this analysis: it became clear to the team from watching the video that they were taking too long to shoot. The walk that the photographer was taking was unnecessarily long. And the same was true for the stylist. The set was too large, or at least larger than it needed to be. In short, flow production was needed.

Keep It Simple: Two Birds, One Stone

Not only were the photographer and stylist spending too much time walking around the set but while the assistant was changing the set over the photographer was idle waiting to shoot.

One of the central tenets of lean and flow production is the elimination of large quantities of waste and focusing on value add steps. This waiting for the set change kept the photographer from the value add step of capturing product images and was also an example of waste in their process. The team quickly identified both issues and had an idea to address both problems with a single solution.

If they were to shrink the size of the set to reduce the time spent walking they’d have additional space and could build a second set that would eliminate the need for any set changes. This meant the photographer could move between the two sets without waiting and the stylist could be prepping products on one while the photographer shot on the other.

This ingenious solution meant they’d be able to add more value to the process while also eliminating waste—a win-win for the team.

This exercise proved engaging for the team and simple to do.

"It was a really neat way for the team to see their ideas manifest and most importantly it improved productivity for the most urgent products, getting them online more quickly. And although I was initially very reticent it was a very strong experience. It was particularly inspiring to me to see how much the team could take ownership in what we were doing." - James

No Lasting Change

The adoption of this lean approach was meant to be a wholesale culture change; to one of ongoing problem-solving and moving into continuous improvement.

And while it was successful in many ways, leading to an additional 50% improvement in productivity (beyond the 155% they had already achieved), it ultimately and unfortunately became a discrete project.

The philosophy of lean is focused on achieving standardization in process, one which is repeatable and stable so that deviations can be easily identified and assets can be produced quickly. Once an expected performance is known, you can very quickly and easily see when issues arise and you’ve moved away from the baseline.

The challenge for James’ team was that when they had the consultants around they were investing in this initiative and could capture the data they needed. But the data capture was very manual. They had been asking people to fill in spreadsheets and had the consultants doing time and motion studies. They needed all that data but it wasn’t sustainable and ironically the data capture itself ended up becoming more waste in the process.

He then tried to find a system in the marketplace that would support the team and provide the visibility they needed for ongoing evaluation and improvements, but to no avail.

"So ultimately, I left John Lewis after 6 and a half years, to join Creative Force with the express intent of delivering and building this tool because after my research I realized there wasn’t a viable solution out there." - James

A Brief History of Lean

The foundation of lean philosophy traces back to manufacturing processes and Toyota’s famously efficient assembly line. The architect of the Toyota Production System, Taiichi Ohno, is considered the “father of lean.”

His obsession with constantly trying to reduce the production timeline by focusing on only doing the things that add value and eliminating the things that lead to waste is the bedrock of lean principles.

"All we are doing is looking at the timeline, from the moment the customer gives us an order to the point when we collect the cash. And we are reducing the timeline by reducing the non-value adding wastes." -Taiichi Ohno

Lean Becomes Flow Production

At Creative Force, we embrace lean principles in their applications to studio production and eCommerce content creation broadly, but we think of them as enabling a steady stream of production, or flow if you will, so that’s the term we’ve coined.

And the premise involved is simple. Flow production is lowering the work-in-progress, increases throughput, and creating shorter cycle times. That’s it.

No overpriced consultant jargon, just a focus on reducing the complexity in production, eliminating wasted effort, and adding more value to the process by delivering more creative content to drive sales.

"To deliver a product through the process, in terms of the tasks actually performed, steaming, prepping, styling, shooting, and some post-production work, it probably only takes an hour, 2 hours of tasks, of time working on the product, but typically we see that taking 5, 6, 8, 10 days. So by reducing work-in-progress and reducing batch production, there’s a lot of potential to really speed up how quickly we can get products to market and that’s massively important when you have product that is ‘in stock not live.’ Reducing lead times and WIP is going to help massively, and that’s the idea of flow production." - James

Little’s Law, Big Impact

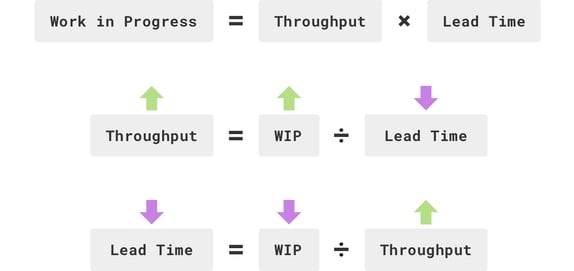

Business leaders spend a lot of time focused on throughput and lead time but often overlook another key piece of the equation that defines flow production and that critical piece is work-in-progress. All the products that could be throughput but aren’t, like samples waiting to be shot or images waiting to be retouched, etc., all of that is work-in-progress.

The relationship between these three facets of the flow production process is defined by Little’s Law.

Without getting too mathematical, in simplest terms, the relationship is this:

If you want to increase throughput, you have two options: 1. Increase WIP while maintaining your lead time, or 2. Decrease your lead time

If you want to decrease lead time, again only two options: 1. Decrease WIP while maintaining your throughput or 2. Increase your throughput

So all three elements are related and if you manipulate (or change) one of them in the system, the others will respond directly.

It’s that simple and below are all the equations expressed.

Help Me Understand. I Don’t Speak Greek

Back to James’ story.

Unable to find a solution himself, he joined the team at Creative Force to help in creating a tool to market that simultaneously touched the entire production process and used that end-to-end overview to capture data in a passive and automated way at each touchpoint.

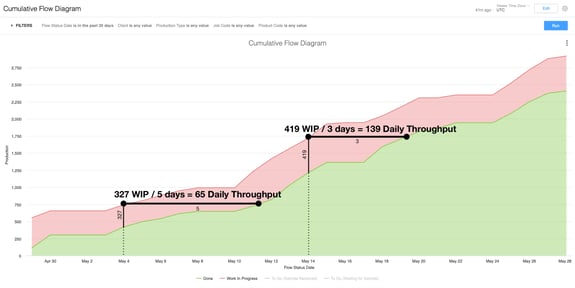

Relating Little’s Law to photography production and making use of this data capture in Creative Force software, studios now have a way to measure their cumulative throughput, or the number of creative assets completed by the end of any given period, their work-in-progress, and the time it takes to complete production for any given assets in the system.

"With this level of data insights, you can very quickly identify bottlenecks. If you go one step deeper [than Little’s Law], looking at cycle time, you can find out why work in progress might be increasing or decreasing. Very visually and quickly you can identify where the bottlenecks exist in your production process and address them in real-time." - Jasper

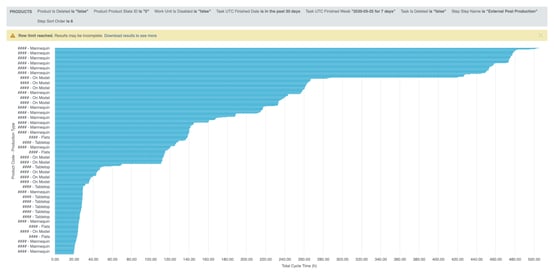

Demo of Creative Force in-app cumulative flow diagram

Demo of Creative Force in-app cumulative flow diagramShow Me the Data

And those measures in the system are just the beginning in flow production.

If you want to go even deeper, there’s almost no limit to what you can explore. You’re really only limited by your imagination and asking the right questions.

Creative Force has drill-down functionality that allows you to look into a specific moment in time on a specific set, with a specific photographer, retoucher, or post-production vendor, product, or product class, or you name the parameters. The sky really is the limit.

Take this graph, for example, that demonstrates the Pareto Rule of 20-80, which states that 20% of your products will take 80% of your cycle time. In this case, there’s a small number of products that are taking much longer (those at the top). The products causing the slowdown can quickly be identified at a glance and any production issues can be addressed.

Nip It in the Bud

This visibility with flow production allows you to address bottlenecks in real-time and then shuttle resources on the fly as needed in whatever form you deem necessary.

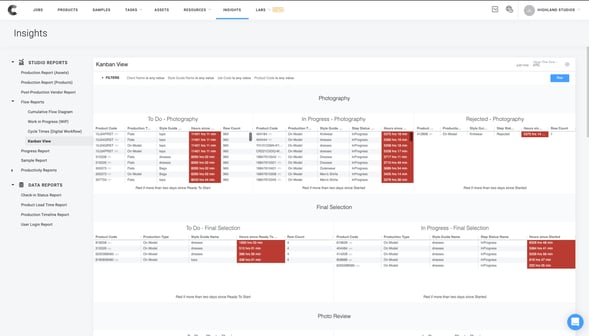

The kanban views allow you to see what tasks are building up behind a team at any stage in production so you can get ahead of bottlenecks by addressing them as you see them cropping up. If you become aware that a team is getting overwhelmed, at the photography step, in this case, you have the opportunity (and visibility) to address the challenge or bring in some freelancers to help relieve that issue as needed.

Armed with Data. Now to Improve Processes

Now that access to real-time data is no longer the limiting factor, performance can be measured and tracked against a baseline. This allows for the development of consistent and repeatable processes, the prerequisite of any improvement efforts in flow production.

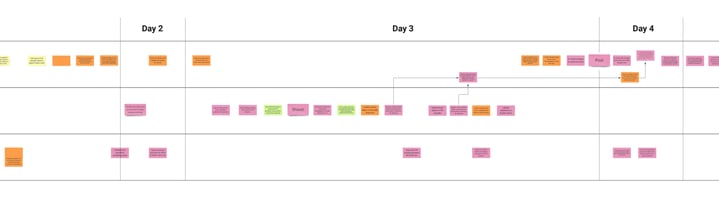

James recently consulted with a client and developed a process map in which they identified 68 steps in their production process which took 7 days in total.

Part of this lean exercise is to analyze not just how you’re doing things but what you’re doing, with a hyper-focus on the value add steps. Answering the important question of how things can be delivered quickly at a higher quality.

Upon review with the client, of the 68 steps, arguably only 3 really added value:

- Building outfits which were then presented at daily styling meetings

- Shooting the product

- And any post-production work.

That’s it!

The rest were either necessary work that led to a value-add step or they were waste that could be eliminated.

Here are just a few examples of the waste steps that came out of their analysis:

- Processing and returning duplicate samples

- Reshooting products that have already been shot

- Contact sheets sent to the client at lunchtime and close of day for approval

- Re-shoots due to creative direction

- Too many shots per product

And this is not atypical. Lean analysis suggests that 95% of all processes are waste in some form.

So now that the value-add steps and the waste steps had been clearly identified the team could set about optimizing for the steps that were necessary to prepare for the value-add steps, eliminate the wasted effort steps like batch production, and spend their newfound free time on those three value-add steps.

"Once you start looking at things from a customer’s perspective, identify how little value add there is, and all the waste there is to address. You can then start to be quite creative and think about how you can address that waste and remove these steps from the process rather than accept a rather complex and flabby way of working."

- James

The Takeaways

At the end of the day, the implementation of the flow production method into the art of capturing moments elevates everything. This method streamlines the process of image creation, lending itself to the creation of a series of quality pieces in a timely and cost-efficient manner with the ability to scale easier. The assembly line setup optimizes the organization of procedures, leading to a seamless and well-ordered output. With flow production in play, the photo studio can boldly produce images that surpass expectations and are defined by their quality. This innovative approach to image creation is a hallmark of the photo studio's commitment to excellence and their pursuit of creativity. It allows them to craft images that not only meet their high standards but offer an added layer of distinction, a testament to the artful essence of their work.

"If you want your team to be the owner of a change, make them authors of the change. Bring them in as early as you can, and let them be party to building what it looks like, because in that way they feel a real sense of skin in the game, like ‘this is something that we’ve designed.’" - James

"Lean talks about the tightening of a bolt, and essentially it’s only the last turn of the bolt that tightens it that’s adding value, the rest of your effort to get it down the threads is waste and so waste is everywhere. When you think you’ve eliminated some, you’ll find some more."

"Lean is all about doing less... better."

Oh, and James and the consultants ended up becoming good friends and they all still keep in touch to this day. Flow production in photo studios is alive and well with him and his team.

Check out the on-demand recording for the full conversation with James and Jasper about lean principles, our concept of flow production, and how to use data to eliminate waste and add more value without more cost.

Plus, all the other episodes in our Remote Studio Solutions Webinar Series are available on-demand to save as well, with even more tips from studio leaders to help you navigate.